The ball milling toughness of WFA F16

The ball milling toughness of WFA grain (White fused alumina) generally does not have a fixed range. It depends on the purity, crystal structure, particle size, and manufacturing process. According to the requirements of GB/T 23538-2023, the ball milling toughness test method of WFA grain is ball milling toughness test. The abrasive wear rate caused by the rotation of a steel ball over a certain period of time is used as the criterion.

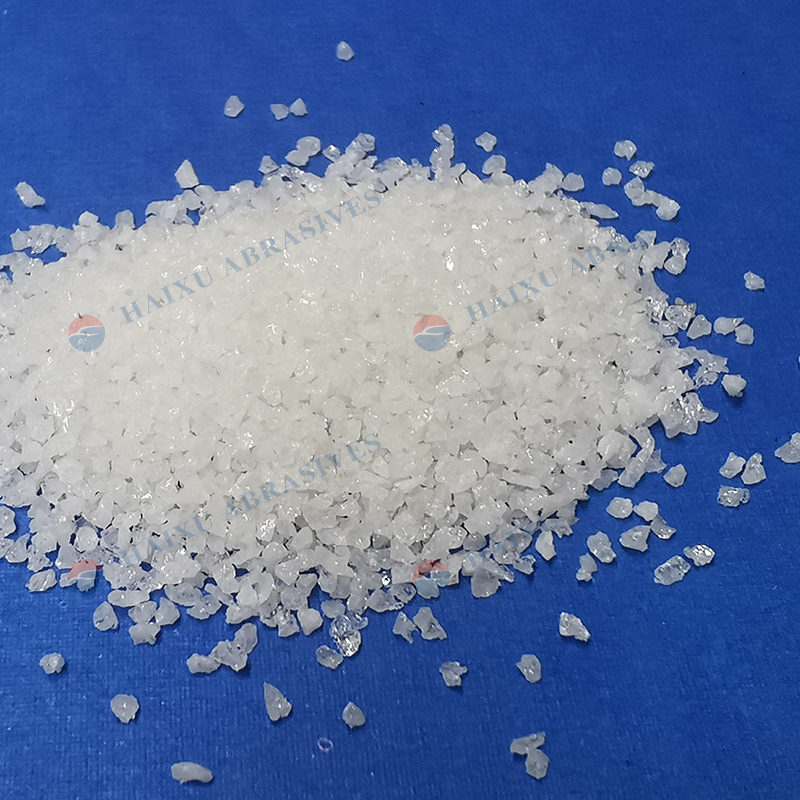

Taking WFA F16 as an example, the ball milling toughness of ordinary white fused alumina (Al₂O₃ purity 99.0%~99.3%) is typically 40-42%; the ball milling toughness of high-purity white fused alumina (Al₂O₃ purity ≥99.5%, high proportion of α-Al₂O₃ crystal form) is 45-50%. Higher ball milling toughness indicates stronger resistance to breakage, better toughness, and better wear resistance of the white fused alumina particles.

The quality of white fused alumina varies among different manufacturers. Key factors affecting toughness include:

1. Purity: Impurities (such as SiO₂ and Fe₂O₃) can disrupt the integrity of α-Al₂O₃ crystals, reducing particle toughness.

2. Bulk Density: Higher bulk density results in higher ball milling toughness.

3. Production Process: WFA produced in a stationary furnace exhibits better toughness than that produced in a tilting furnace.

4. Particle Size: Coarse-grained WFA (e.g., F16, F24) has fewer internal defects. In the meantime, it gets higher toughness than fine-grained (e.g., 200F, 325 F) products.